Case Study

The Challenge:

A global eyewear manufacturer wanted an automated cleaning process line for their glass lens manufacturing plant in Ireland.

The APS Solution:

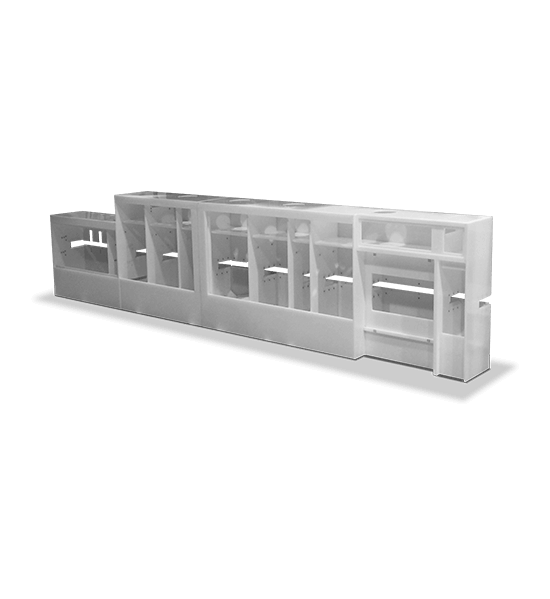

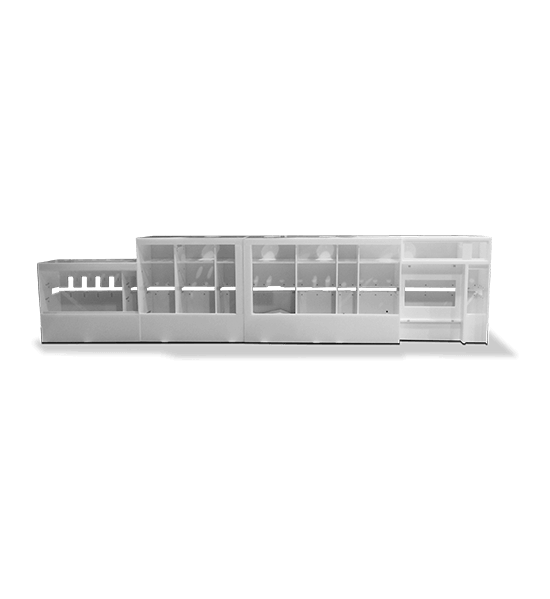

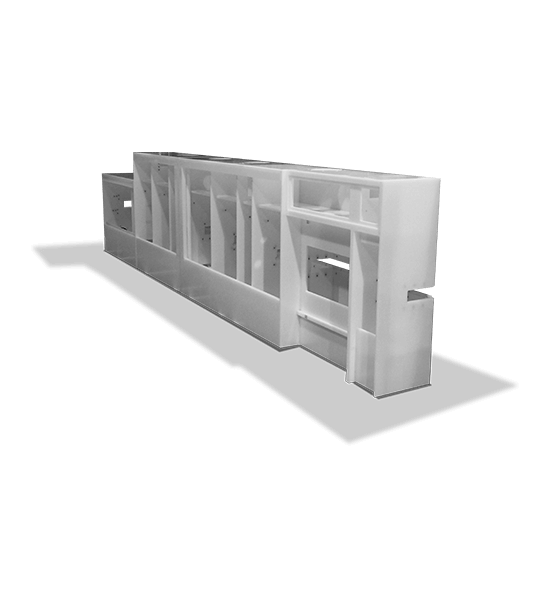

We worked closely with our customer’s engineers to refine a continuous cleaning process tank design. When complete, the process tank included 10 individual cleaning, rinse and drying stations all fed by a continuous conveyer system which moved the lenses through the process tank. The entire process tank was 22-feet long, 5-feet tall , and 3-feet deep. We built in metric stainless steel threaded inserts and couplings for fluid flow in and out of the individual stations.

The Result:

Irish eyes were smiling when they saw what this system could do for quality and production. I’ve been told there’s a pint of Guinness with my name on it next time I visit Dublin. Maybe two pints.